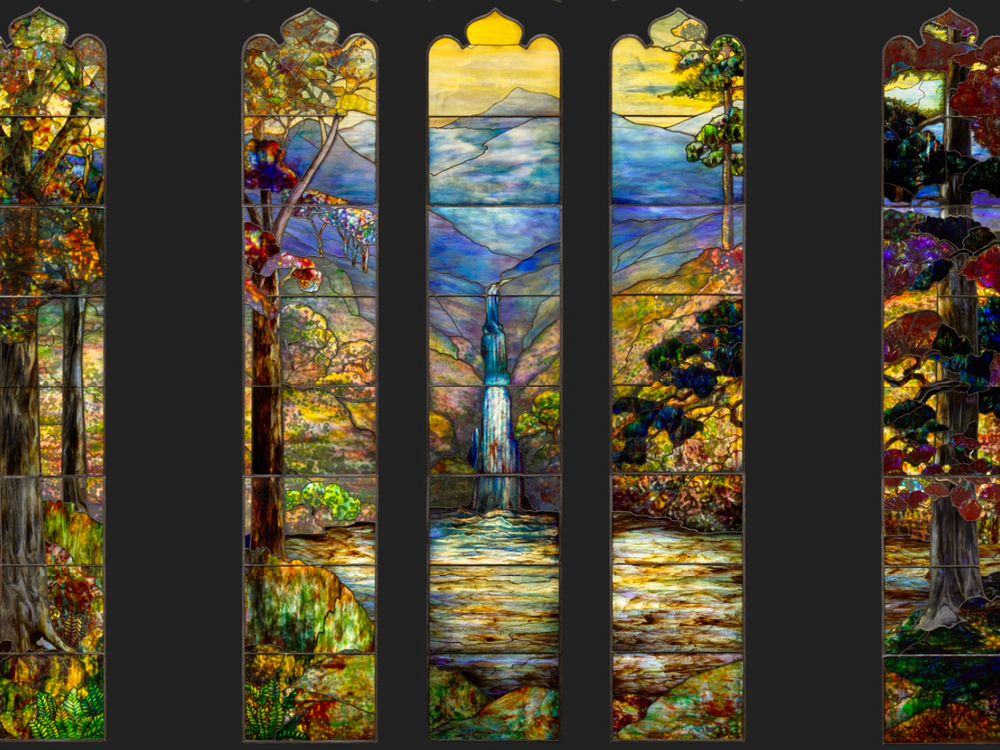

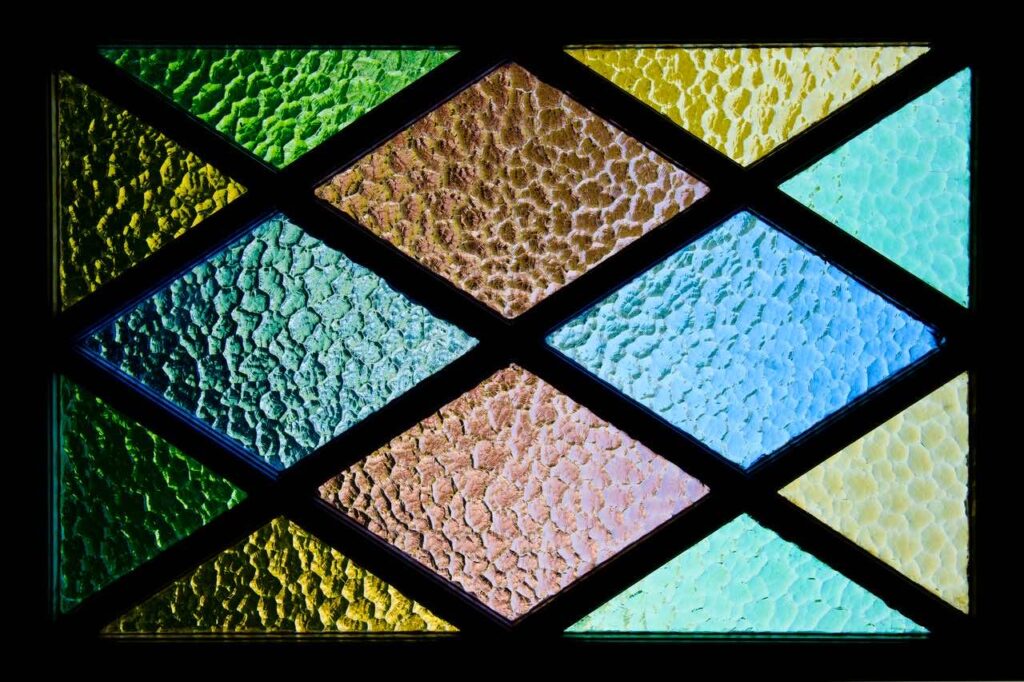

Stained glass is colored glass designed for cutting and laying out in the form of mosaic paintings. It is used for window curtains, lampshades for lamps, shutters, sculptures, and drinking bowls for birds.

Stained glass is subject to accidental external influences like any other glass object. For example, there are cases when Tiffany stained glass inadvertently breaks or deforms.

The stained glass was made by someone incorrectly, in violation of technology. In the future, such stained glass will be easily deformed and broken. Seams of poor-quality stained glass are oxidized. As a result, white salt stains appear on the seams.

Then we face the question — what to do with such stained glass?

You can order a new stained glass window. It is the simplest solution but not the best if the stained glass window is valuable to you. We suggest you try to do stained glass repair yourself.

Stained glass repair

A simple DIY for repairing stained glass products

Stained glass is colored glass designed for cutting and laying out in the form of mosaic paintings. It is used for window curtains, lampshades for lamps, shutters, sculptures, and drinking bowls for birds.

Stained glass is subject to accidental external influences like any other glass object. For example, there are cases when Tiffany stained glass inadvertently breaks or deforms.

The stained glass was made by someone incorrectly, in violation of technology. In the future, such stained glass will be easily deformed and broken. Seams of poor-quality stained glass are oxidized. As a result, white salt stains appear on the seams.

Then we face the question — what to do with such stained glass?

You can order a new stained glass window. It is the simplest solution but not the best if the stained glass window is valuable to you. We suggest you try to do stained glass repair yourself.

Is it always possible to do stained glass window repair?

Tiffany stained glass windows are almost always repairable. Unlike pseudo-stained glass and other derivatives that can not be repaired to new condition.

Restoration is carried out without damaging the pattern of stained glass. Also, if necessary, you can strengthen and reinforce the stained glass structure.

There are cases when you can’t find the necessary stained glass for repairing your glass product. It may happen when, for example, the stained glass is more than 50 years old or made not on a factory glass but a master one. In these cases, the restoration process takes more time. All the time in such cases goes in search of the original piece of glass from the proper manufacturer.

The complexity of stained glass restoration with a classic stained glass high-temperature painting should also be mentioned. It is the process when you need to copy the original image that is lost. But mostly, these are pretty rare cases.

In general, stained glass can be repaired in the following cases:

- Stained glass is deformed;

- The individual parts are cracked;

- Melted seams from overheating with an incandescent lamp;

- The seams have oxidized with age;

- Sagging of stained glass ceiling;

- Stained glass repair of Tiffany lamps;

What tools will you need for stained glass repair?

You will need the following items for repair:

- Goggles

- Oil

- A small cup of oil

- Glass cutter for stained glass

- Stained glass

- Marker

- Gon/ square

- Cutting disc

- Nippers

- Pliers for cutting glass

What does the process of stained glass repair look like?

The best way to explain this process is a real example. For example, we need to restore a stained glass lamp on a bronze stand.

A part of the stained glass was deformed under a powerful incandescent lamp. It led to the deformation of brazed seams, cracks in the mirror, and loss of strength of the overall structure of the stained glass product. Stained glass repair is possible and makes sense in this case.

It is necessary to disassemble this Tiffany lamp and to choose identical glass.

Next, you need to strengthen the stand with special fittings and stained glass elements.

Then assemble everything to its original appearance.

It would be best if you also eliminated factory defects in soldering.

How to cut stained glass?

You will need to cut the stained glass before starting stained glass repair. It would help if you did it so that it fits under your frame, and secondly, you do not accidentally damage it.

Follow the steps below to cut stained glass:

- Clean a large, flat, and clean surface.

- Lubricate the glass cutter with grease.

Immerse the glass cutter in a small amount of oil. Be sure to immerse it in oil before each cut to extend its life and facilitate the process of scratching.

- Mark the line.

Use a marker and a square to mark the line you want to cut the glass. Scratch the glass, holding the glass cutter vertically and confidently moving it along the cut line.

- Beat off the glass along the cut line.

Clamp the glass on each side, placing your fists under the glass and your thumbs over it. Holding the glass firmly, shake your hands up and down.

And now we move on to a more challenging stage – cutting glass along curved lines.

- Scratch the glass.

Move the glass cutter along the specified line to scratch the glass. Hold the main piece of glass firmly in your hand and fix the part you want to remove in the scratched line with pliers. Shake the pliers up and down to tear off the glass gently.

- You can scratch sharp bends with a few straight lines.

To make the curve smoother, remove all the extra pieces of glass by wrapping the glass with forceps to the cut line. With their help, carefully break off unnecessary parts of the glass.

- Smooth or round the edges of the cut glass with a glass cutter.

Please turn on the cutter and hold the glass gently but firmly, applying it to a rapidly rotating wheel. A diamond crumb is used to grind unnecessary glass.

The following essential nuances should be kept in mind when cutting the stained glass:

- Do not try to cut a small piece from a large sheet of stained glass. It is easier to cut off a small amount of glass while minimizing the risk of accidental damage or breakage of the entire sheet of glass.

- While scratching the glass, maintain constant pressure along its entire length in one continuous motion. The uneven pressure or stopping the movement of the glass cutter can lead to cracks.

- You can use any oil, including vegetable oil, to lubricate the glass cutter.

- Do not scratch the same line more than once. It can damage the glass cutter. If you make a mistake while marking, go on. And then cut off the excess glass by applying additional scratches or using the forceps to work with the glass.

- After cutting stained glass, always clean the work surface of the table with a small brush to remove small fragments of glass.

- Using a cutter, wear goggles and add water to the machine according to the manufacturer’s instructions.

- Cut the glass in a standing position.

- Using templates for cutting stained glass, circle them with a marker and cut the glass only on the inside of the cut line.

- And again, wearing goggles is a must! Be very careful when working with the areas of glass where the cut was made. There will be tiny shards of glass that can injure your fingers or get in your eyes.

How do you restore a pattern, improve the color, and finish the damaged elements?

Necessary materials and tools

The technology of self-manufacturing stained glass is considered an example of artistic painting or the so-called pouring technique.

You will need the following items for work:

- stained glass paints without firing;

- contour;

- acrylic varnish to fix the finished image;

- stencil;

- marker for transferring the image to the surface;

- conical brushes to correct the pattern;

- color mixing palette;

- glass product;

- acetone and alcohol for degreasing the surface and wiping stains;

- toothpicks and cotton swabs;

- a rag for wiping brushes;

- solvent

Be sure to use the same type of solvent as the paint.

Step-by-step instructions

When the materials are ready, you need to read the detailed instructions on drawing on stained glass.

First, degrease the surface with detergent, alcohol, or acetone. The paint must lie better on the surface.

Place the stencil under the base of the painting. After that, transfer the image with a marker. Then give the drying time indicated on the tube.

It is followed by a gradual filling of the fragments from the center, moving to the edges of the figure. First, fill in the details of one color, then another, etc. When the colored information is ready, fill in the background between them. It is better to use quick-drying varnish.

Now you have to wait for it to dry completely. Then cover the picture with colorless varnish to fix it and simplify the care of the product.

Important Tip! It is better to put white paper or fabric under the painted base, so colors and shades are better visible.

General recommendations for the stained glass care

To preserve the natural color and transparency of stained glass surface, clean it of dirt carefully. Use only mild soaps and non-aggressive care products.

Remove heavy soiling with a mild detergent. After cleaning, be sure to wipe dry with a lint-free cloth.

If you don’t want any deformation and destruction of the composition, we recommend avoiding excessive pressure when cleaning. Clean the painted products without touching the colored parts.

Glass surfaces are resistant to the adverse effects of ultraviolet light and moisture, although they look fragile.

Painted areas require careful care. Do not use force, aggressive household chemicals, abrasive cleaners, hard sponges, and brushes.

After some time, the metal parts are subject to corrosion, which leads to destruction. To avoid this unpleasant effect, it is important to thoroughly wipe the product after each wash, removing excess moisture.

It is enough to follow these several rules during operation and care to make your stained glass products serve you for many years.

But even if you do not feel like doing all these things yourself, a window glass replacement company can repair or replace everything, including doing stained glass repair.

Suppose you value your stained glass, or it has artistic value. In that case, the excellent variant is ordering repair and restoration in our company.